- Home Page

- Company Profile

-

Our Products

- Industrial Gasket

- EPDM Gasket

- Spiral Wound Metallic Gasket

- Spiral Gasket

- Corrugated Metal Gasket

- Rubber O Ring Gasket

- Automotive Gasket

- Solid Metal Gasket

- Carbon Graphite Gasket

- Asbestos Gasket

- Ring Joint R-Octagonal Gasket

- PTFE Envelope Gasket

- EPDM Rubber Gasket

- Non Asbestos Gasket

- Ceramic Gasket

- CAF Gasket

- Envelope Gasket

- Oval Gasket

- Graphite Gasket

- Flat Metal Gasket

- Expansion Joint Gasket

- Flange Gasket

- PTFE Gasket

- Custom Gasket

- Metallic Gasket

- Seal Strip Rubber Gasket

- Laminated Gasket

- Exhaust Gasket

- Tapper Ring Gasket

- Serrated Metal Gasket

- Non-Metal Gaskets

- Camprofile Gaskets

- Spiral Wound Gaskets

- Ring Joint Gaskets

- Rubber Gaskets

- Extruded & Molded Gaskets

- Ceramic Fiber Gaskets

- Carbon & Graphite Gaskets

- Metal Shims

- O Rings

- Expansion Joints

- Hylam Rod

- Metal Gaskets

- Insulated Sheet

- PTFE & PTFE-Based Gaskets

- CAF and NACF Cut Gasket

- Metal Jacketed Gasket

- PTFE Envelope Gaskets

- PTFE Gasket

- Rubber Gasket

- Spiral Wound Gasket

- Graphite Gasket

- Kammprofile Gasket Manufacturers

- Solid Gasket

- Ceramic Gaskets

- Ring Type Joint Gasket

- Corrugated Metallic Gaskets

- Hylum-bakelite Fabricated Insulation Kit Gaskets

- Asbestos & Non Asbestos Gland Packing

- ASBESTOS ROPS CLOTHS AND ETC

- CAF & NONASBESTOS GASKET

- COPPER GASKET

- G TYPE GASKET

- INSULATING KIT

- JACKETED GASKET

- MILBOARD GASKET

- PTFE ENCAPSULATED VITON O RING

- PTFE PRODUCTS

- RUBBER PRODUCTS

- SERRATED GRAPHITE GASKET

- SS CORRUGATED GASKET

- Industrial Gasket

- Gallery

- Contact Us

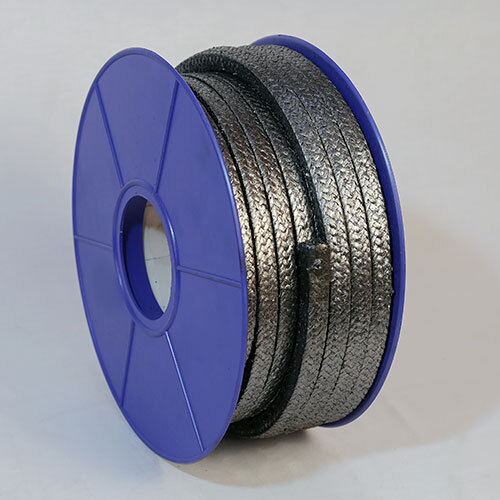

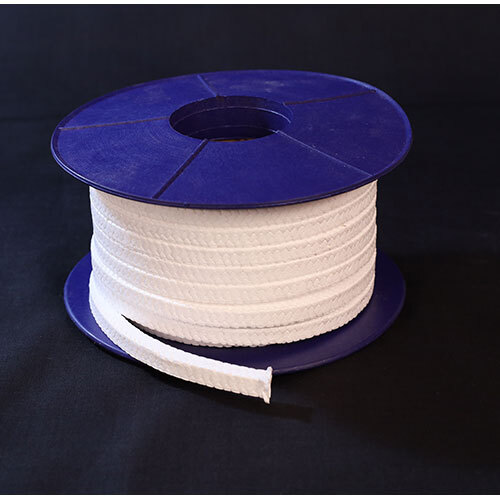

Ptfe Universal Rope Gaskets

1850 INR/Piece

Product Details:

- Product Type Ptfe Gaskets

- Material Ptfe

- Application Industrial

- Color White

- Click to view more

X

Ptfe Universal Rope Gaskets Price And Quantity

- 5 Piece

- 1850 INR/Piece

Ptfe Universal Rope Gaskets Product Specifications

- Ptfe

- White

- Industrial

- Ptfe Gaskets

Ptfe Universal Rope Gaskets Trade Information

- 1000 Piece Per Week

- 7 Days

Product Description

The synthetic fluoropolymer of tetrafluoroethylene is used to make PTFE (polytetrafluoroethylene) products. The substance, which is most widely referred to by its trademark name PTFE, is extremely hydrophobic, has one of the lowest coefficients of friction, and is resistant to the majority of chemicals due to its inert nature. To lessen creep under high pressures and temperatures, PTFE gaskets can be strengthened with fillers like carbon or graphite.

To accommodate a broad range of sealing requirements, we precisely cut both virgin and composite PTFE gasket profiles.

Production of PTFE Gaskets

Using in-house CNC equipment, we can cut our PTFE gaskets and seals to exact tolerances in small or large quantities to meet customer specifications. Our manufacturing procedure guarantees accurate, economical, and efficient output.

Our turnkey gasket manufacturing solutions were created to assist customers with prototype and material specification as needed. CAD gasket design, standard and custom manufacturing, and distribution are frequently included in this. Every gasket is provided in accordance with accepted national and international standards.

PTFE's salient characteristics include chemical resistance.

- High dielectric insulating strength,

- Resilience to temperatures between -200oC and +260oC

- Low coefficient of friction

- Good moisture resistance

Materials for PTFE Gaskets

By offering resistance to chemicals, heat, and liquids, PTFE materials can be modified during manufacturing to meet a variety of sealing applications. Virgin, expanded, and filled PTFE are exceptionally adaptable materials that provide stability and good recovery across a broad temperature and pressure range. The material is generally non-corrosive in chemical operations and can be reinforced with fillers like glass, carbon, or speciality composites like metal detecting PTFE.

Expanded Virgin PTFE is a clear choice for applications where connections have worn out or become damaged due to its enhanced compressibility properties. Virgin and expanded materials are provided in accordance with FDA and MHRA regulations.

|

Materials |

Temperature Range |

PN Range |

|

Virgin |

-200oC up to +260oC |

2.5/320 |

|

Blue Food Quality |

-200oC up to +260oC |

2.5/320 |

|

Expanded PTFE |

-240oC up to +270oC |

2.5/320 |

|

Carbon Filled |

-200oC up to +260oC |

2.5/320 |

|

Glass Filled |

-260oC up to +250oC |

2.5/320 |

|

Stainless Steel Filled |

-200oC up to +260oC |

2.5/320 |

|

Bronze Filled |

-200oC up to +260oC |

2.5/320 |

|

Metal Detectable |

-200oC up to +260oC |

2.5/320 |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email